Characteristics of NdFeB Magnets

Summary of Neodymium Iron Boron Physical Properties (NdFeB) magnets

A neodymium magnet (also known as NdFeB, NIB or Neo magnet) is a permanent magnet made from an alloy of neodymium, iron, and boron to form the Nd2Fe14B tetragonal crystalline structure.They are the most widely used type of rare-earth magnet.

| Items | Parameters | Unit | Reference Range |

|---|---|---|---|

| Regular Physical Properties | Density / ρ | g/cm3 | 7.40-7.80 |

| Vickness Hardness / HV | – | 550-650 | |

| Electrical Properties | Electrical Resistivity | μΩ·m | 1.4 |

| Mechanical Properties | Compressive Strength | MPa | 1050 |

| Tensile Strength | MPa | 80 | |

| Bending Strength | MPa | 290 | |

| Thermal Properties | Thermal Conductivity | W/(m·K) | 6-8 |

| Coefficient of Thermal Expansion | 10-6/K | C⊥: -1.5, C∥: 6.5. |

Magnetic properties

There are eight different standard grades of neodymium magnets typically used in commercial applications today ranging from N35 to N52. Neodymium magnets are graded by their maximum energy product (BH)max with N52 grade neodymium providing the greatest magnetic performance and N35 being the weakest. The magnetic properties of the various grades of neodymium magnets are adjusted by using varying amounts of rare earth elements in the alloy mixture, with each element adjusting the characteristics of the material in a different way. Below, you can see the list of standard neodymium magnet grades and their magnetic properties below.

| Grade | Remanence | Coercive Force | Intrinsic Coercive Force | Max. energy product | Max. Operating Temperature |

|---|---|---|---|---|---|

| BR | HcB | Hcj | (BH)max | ||

| mT | kA/m | kA/m | MGOe | ||

| N35 | 1180-1240 | ≥10.94 | ≥12 | 33-36 | 80°C |

| N38 | 1220-1260 | ≥11.31 | ≥12 | 36-40 | 80°C |

| N40 | 1260-1300 | ≥11.40 | ≥12 | 38-42 | 80°C |

| N42 | 1300-1320 | ≥11.40 | ≥12 | 40-44 | 80°C |

| N45 | 1330-1380 | ≥11.40 | ≥12 | 42-46 | 80°C |

| N48 | 1370-1420 | ≥11.40 | ≥12 | 45-49 | 80°C |

| N50 | 1410-1440 | ≥10.50 | ≥12 | 48-51 | 80°C |

| N52 | 1430-1460 | ≥10.50 | ≥11 | 50-53 | 80°C |

| N33M | 1140-1170 | ≥10.65 | ≥14 | 30-35 | 100°C |

| N35M | 1180-1220 | ≥10.94 | ≥14 | 33-36 | 100°C |

| N38M | 1220-1260 | ≥11.4 | ≥14 | 36-40 | 100°C |

| N40M | 1260-1300 | ≥11.78 | ≥14 | 38-42 | 100°C |

| N42M | 1300-1320 | ≥12.14 | ≥14 | 40-44 | 100°C |

| N45M | 1330-1380 | ≥12.43 | ≥14 | 42-46 | 100°C |

| N48M | 1370-1430 | ≥12.80 | ≥14 | 45-49 | 100°C |

| N50M | 1410-1440 | ≥13.1 | ≥14 | 47-51 | 100°C |

| N52M | 1430-1460 | ≥13.1 | ≥14 | 50-53 | 100°C |

| N30H | 1080-1120 | ≥10.14 | ≥17 | 28-31 | 120°C |

| N33H | 1140-1180 | ≥10.70 | ≥17 | 31-35 | 120°C |

| N35H | 1180-1220 | ≥11 | ≥17 | 33-37 | 120°C |

| N38H | 1220-1260 | ≥11.46 | ≥17 | 36-40 | 120°C |

| N40H | 1260-1300 | ≥11.83 | ≥17 | 38-42 | 120°C |

| N42H | 1300-1320 | ≥12.21 | ≥17 | 40-44 | 120°C |

| N45H | 1320-1360 | ≥12 | ≥17 | 42-46 | 120°C |

| N48H | 1370-1420 | ≥12.86 | ≥17 | 46-49 | 120°C |

| N50H | 1410-1440 | ≥13.24 | ≥17 | 48-52 | 120°C |

| N52H | 1420-1460 | ≥12.8 | ≥17 | 50-54 | 120°C |

| N30SH | 1110-1140 | ≥10.18 | ≥20 | 28-32 | 150°C |

| N33SH | 1140-1180 | ≥10.75 | ≥20 | 31-35 | 150°C |

| N35SH | 1180-1220 | ≥11 | ≥20 | 33-36 | 150°C |

| N38SH | 1220-1260 | ≥11.5 | ≥20 | 36-40 | 150°C |

| N40SH | 1260-1300 | ≥11.88 | ≥20 | 38-42 | 150°C |

| N42SH | 1300-1320 | ≥12.26 | ≥20 | 40-44 | 150°C |

| N45SH | 1320-1360 | ≥11.5 | ≥20 | 42-46 | 150°C |

| N48SH | 1370-1400 | ≥12.85 | ≥20 | 44-47 | 150°C |

| N50SH | 1410-1440 | ≥11.5 | ≥20 | 46-49 | 150°C |

| N28UH | 1040-1100 | ≥9.86 | ≥25 | 26-30 | 180°C |

| N30UH | 1100-1140 | ≥10.24 | ≥25 | 28-32 | 180°C |

| N33UH | 1140-1180 | ≥10.8 | ≥25 | 31-35 | 180°C |

| N35UH | 1180-1220 | ≥11.09 | ≥25 | 33-36 | 180°C |

| N38UH | 1220-1260 | ≥11.54 | ≥25 | 36-44 | 180°C |

| N40UH | 1260-1300 | ≥11.94 | ≥25 | 38-42 | 180°C |

| N42UH | 1300-1320 | ≥12.32 | ≥25 | 40-44 | 180°C |

| N45UH | 1320-1360 | ≥11 | ≥30 | 42-46 | 180°C |

| N28EH | 1180-1240 | ≥10.3 | ≥30 | 26-30 | 200°C |

| N30EH | 1180-1240 | ≥10.6 | ≥30 | 28-32 | 200°C |

| N33EH | 1180-1240 | ≥10.8 | ≥30 | 31-35 | 200°C |

| N35EH | 1180-1240 | ≥11.09 | ≥30 | 33-36 | 200°C |

| N38EH | 1180-1240 | ≥11.54 | ≥30 | 36-40 | 200°C |

| N30AH | 1180-1240 | ≥10.24 | ≥35 | 28-32 | 230°C |

| N33AH | 1180-1240 | ≥10.80 | ≥35 | 30-35 | 230°C |

| N35AH | 1180-1240 | ≥10.7 | ≥35 | 32-36 | 230°C |

Table comparing main NdFeB coating types

| Coating | Thickness(μm) | Color | SST(hrs) | PCT(hrs) | Characteristics |

|---|---|---|---|---|---|

| BW-Zn | 4-15 | Bright blue | ≥24 | – | Secondly commonly used single layer coating. Poor corrosion resistance. |

| Color-Zn | 4-15 | Shining color | ≥48 | – | Corrosion resistance is better than BW-Zn. |

| Ni-Cu-Ni | 5-20 | Bright silver | ≥48 | ≥48 | Most regular used multi-layer coating. Excellent humidity and salt spray resistance. |

| Electroless Ni | 5-20 | Dark silver | ≥72 | ≥48 | Excellent humidity and salt spray resistance with uniform appearance. |

| Ni-Cu-Ni-Au | 5-20 | Golden | ≥72 | ≥96 | Excellent electrical conductivity and decorative performance. |

| Ni-Cu-Ni-Ag | 5-20 | Silver | ≥72 | ≥96 | Excellent electrical conductivity and decorative performance. |

| Ni-Cu-Ni-Sn | 5-20 | Silver | ≥72 | ≥96 | Excellent humidity resistance. |

| Phosphate | 1-3 | Dark grey | – | – | Temporary protection. |

| Aluminum | 2-15 | Bright silver | ≥24 | ≥24 | Noticeable coating. |

| Epoxy resin | 10-30 | Black/Grey | ≥72 | ≥72 | Excellent humidity and salt spray resistance. Superir binding force. |

| Parylene | 5-20 | Colorless | ≥96 | – | Excellent humidity, salt spray, corrosive vapors, and solvents resistance. Free of pore. |

| Everlube | 10-15 | Golden yellow | ≥120 | ≥72 | Excellent humidity resistance. |

| Teflon | 8-15 | Black | ≥24 | ≥24 | High temperature and rub resistance. Self-lubricant and 100% water-proof. |

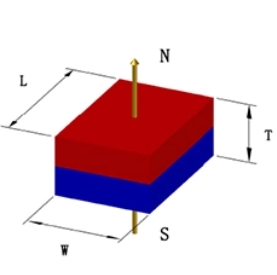

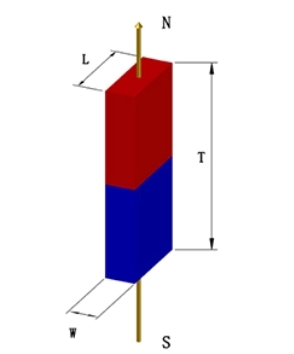

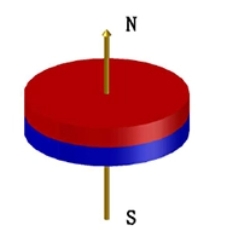

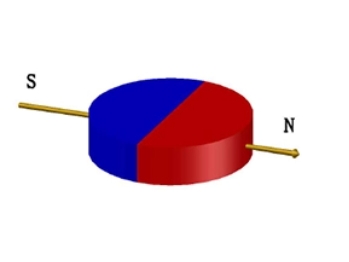

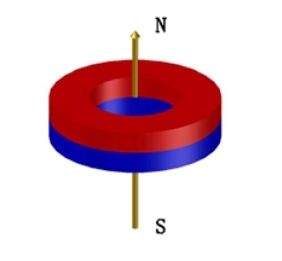

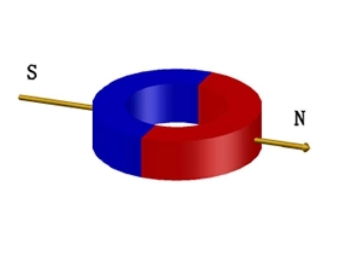

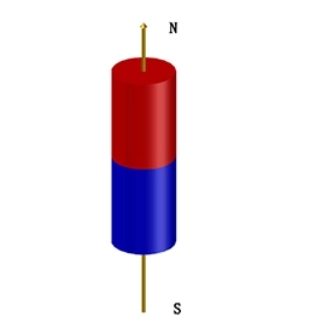

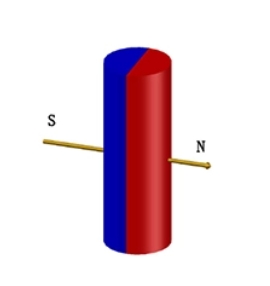

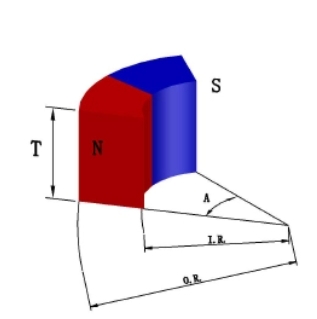

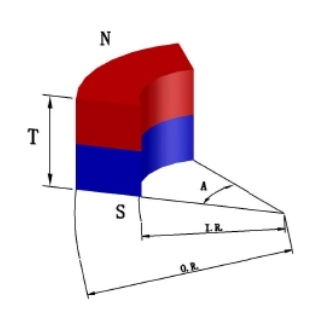

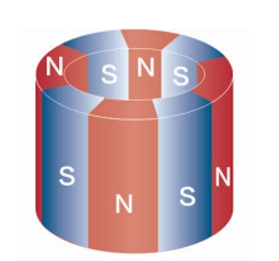

Magnetization Direction